Evaporators

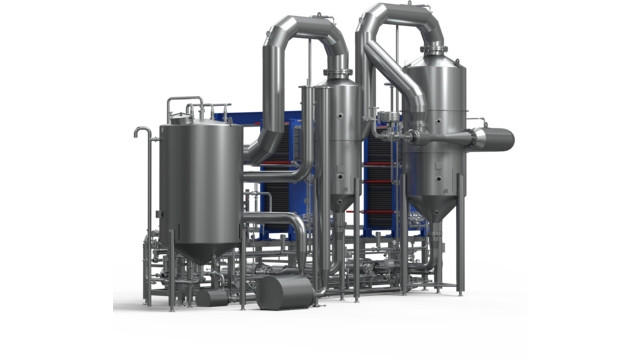

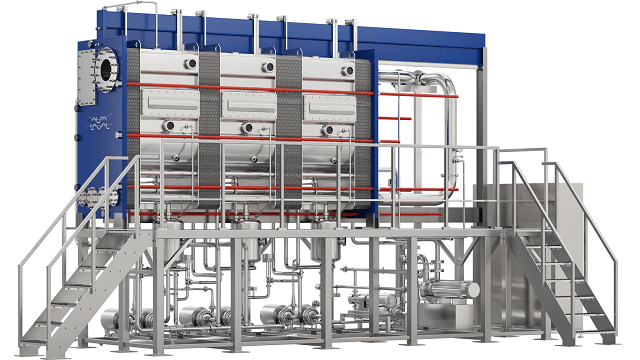

Let Alfa Laval customize a plate evaporation system to meet your exact requirements. Energy-saving and purpose-built, these systems improve thermal efficiency, achieve higher concentrations, boost uptime, and reduce costs. With a long tradition of optimizing plate heat exchangers, Alfa Laval gives you access to expertise and the vast resources of an experienced global sourcing and engineering organization.

Evaporation optimized by the experts

- Achieve higher concentrations while saving energy and adding value to your business

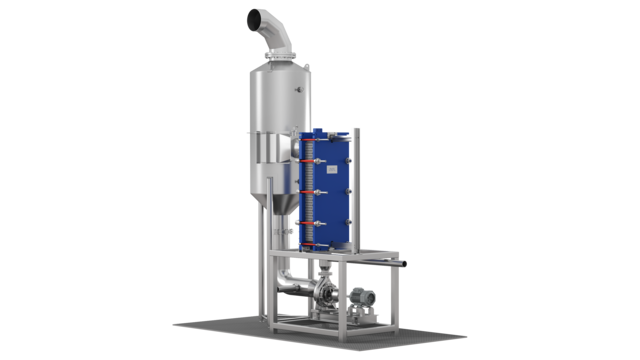

- Cut energy costs and improve process sustainability by adding effects and/or vapour recompression equipment

- Cut energy costs and improve sustainability with thermal vapour recompression, mechanical vapour recompression, or waste heat recovery solutions

- Lower installation costs with compact, space-saving installations

- Get zero or minimum liquid discharge by combining with other Alfa Laval technologies

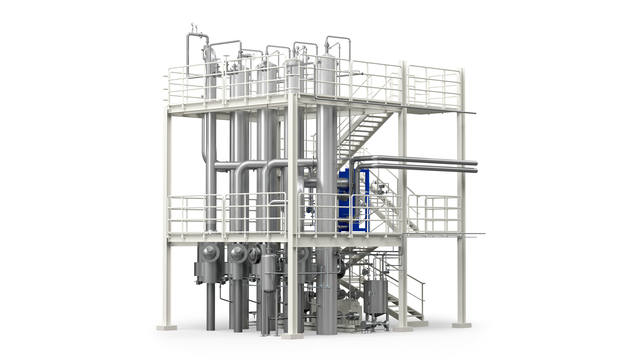

Lower your cost of ownership while increasing sustainability with evaporation systems from Alfa Laval. Tailored to your requirements, these are easy to configure, install, operate and maintain.

Pack high heat transfer efficiency and energy savings into evaporation systems, that are lower in height and weight than conventional evaporators. Versatile, energy-efficient and economical, these evaporators generally fit into the available space in existing buildings yet maximize product quality while minimizing fouling and waste.

Choose from a broad portfolio, backed by a proven track record, vast experience in thermal solutions and separation technologies, and a global service network

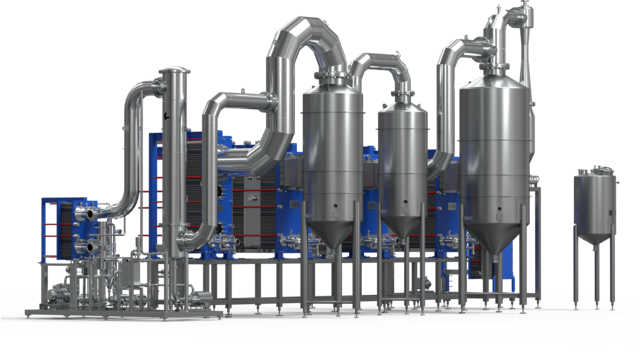

Completely engineered and pre-assembled evaporation systems

Pielietojumi

Food and beverage

- Fruit juices and purées

- Sugars, syrups (corn), honey and confectioneries

- Ethanol stillage

- Meat and vegetable broths

- Gelatine and collagen peptides

- Fermentation products

- Coffee and tea

- Vegetable protein

- Milk and whey protein

- Non-dairy plant drinks (oat, nut, etc.)

- Beer de-alcoholization

- Herbal extracts

Starch and sweeteners

- Sugars (beet, cane, potato, etc.)

- Glucose, dextrose, fructose, maltose

Proteins

- Gelatine

- Stick water

- Meat and fish broths

- Insect protein slurries

- Plant-based proteins

Chemicals and wastewater

- Caustic (NaOH, KOH, LiOH)

- Zero liquid discharge

- Inorganic salts

- Biofuels

Life science/industrial fermentation

- Fermentation broths

- Lysine

- Lactic acids

- Citric acids

- Amino acids

- Yeast extract

Unmatched performance

Get the most economical evaporator for your process needs – right from the start. Take advantage of broad evaporation expertise from Alfa Laval. Get energy-saving, easy-to-maintain evaporation systems at a lower total cost of ownership than comparable shell-and-tube systems.

Compact and flexible

Lower the total cost of ownership with Alfa Laval evaporators. Use less space. Save on installation, operating and maintenance costs. Retrofit additional evaporator capacity into existing buildings cost-effectively. Add more savings to your bottom line.

Optimizing uptime

Alfa Laval offers dedicated service to optimize your evaporation system and ensure more uptime:

- Connected services provide remote support and assistance to achieve improved uptime, high yield and optimized maintenance frequency

- Spare parts for all key equipment readily available

- Service agreements for tailor-made support – from spare parts to troubleshooting and retrofits

Pakalpojumi

Pārtikas sistēmu pakalpojumi

Alfa Laval pārtikas sistēmu pakalpojumi palīdz palielināt jūsu pārtikas sistēmu veiktspēju, maksimāli palielinot jūsu procesu efektivitāti. Tas ļauj jums:

- Nepārtraukti uzlabot savu darbību, lai saglabātu konkurences priekšrocības

- Koncentrēties uz darbspējas laiku, optimizāciju un pieejamību

- Maksimāli palielināt ieguldījumu atdevi visā pārtikas sistēmu dzīves ciklā

Pilot testing and rentals of evaporation systems

Try before you buy. Get expertise and advice from Alfa Laval engineers for the optimum configuration for your evaporation system, including:

- Detailed water analysis and characterization

- Process and water chemistry modelling

- Benchmark and/or pilot testing for moderate- to high-risk applications

- Detailed material compatibility evaluation

- Sample analysis

- Pilot tests

Visit the Alfa Laval Materials Technology & Chemistry Lab and Test Centre in Lund, Sweden, the Alfa Laval Innovation and Test Centre in Nakskov, Denmark, or rent one of our mobile pilot evaporation systems to conduct onsite trials at your plant.