Alfa Laval Olmi

The Alfa Laval Olmi air heat exchanger product portfolio fits a wide range of conditions that can handle pressures up to 613 bar as well as temperatures up to 400°C.

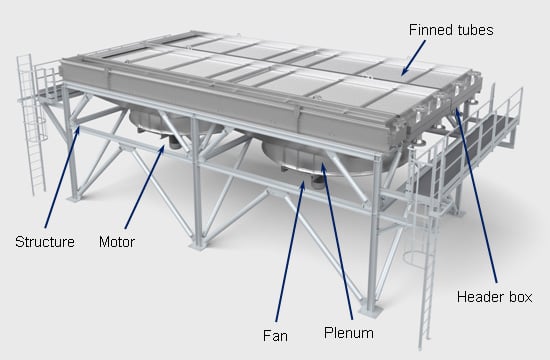

The air cooled heat exchangers are used in refineries, gas, petrochemical and chemical plants and are customized for our customer's needs in tough conditions, complex installations and critical applications.

The air cooled tube bundle cover the complete range of:

- Metallurgies from low alloy and carbon steel, stainless steel, duplex and super-duplex stainless steel, nickel alloys and titanium.

- Plugs, cover or high pressure manifold header boxes design.

- Extruded, L-footed or Embedded aluminum tubes fins.

As well as common configurations we can also supply additional features like:

- Finite element analysis header box verification under severe load cases including nozzle to header join.

- High pressure design up to 700 Bar(g) made by forgings including tube ends to manifold box IBW (Internal bore welding) joint.

- Plug type header box local tube-ends to tube sheets welded joint PWHT through plug hole.

- Low noise emission design (76 db(A) power level) with low noise fan and noise damping panels.

- Resonance vibration free design by spectral analysis check

- Completely pre-assembled modularized units.

- Winterization arrangement made of intake louvers, by-pass louvers, exhaust louvers and enclosure.

- Design and manufacturing of frequency converter cabinets and container units comprehensive of MV/LV transformers, MCC, PLC, frequency converters and cooling.

Technical data:

- Max size and weight: Up to 18m fin tube length, up to 4.4m bundle width, 30 ton

- Design pressure and design temperature:

- Up to 613 bar, up to 400°C

- Motor range: 5kW to 45kW with frequency converter and complete cabinets

- Fan size: 1.8 - 5.5m

Darbības pamatprincipi