Plakanās lokšņu membrānas

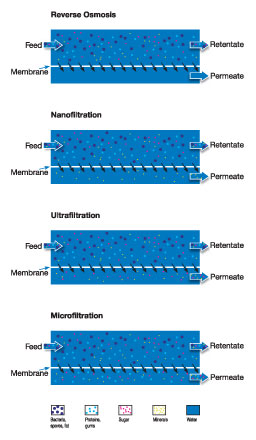

Alfa Laval manufactures polymeric membranes for use in an extensive range of processes applied in the food, beverage, dairy, biotech and pharmaceutical industries. Our membranes cover all cross-flow filtration processes: reverse osmosis, nanofiltration, ultrafiltration and microfiltration

Semi-permeable, polymeric membrane

The basic technology behind membrane filtration involves using a semi-permeable membrane to separate a liquid into two distrinct streams.

Pumping this liquid across the surface of the membrane creates a positive trans-membrane pressure that forces any components smaller than the porosity of the membrane to pass through, forming the permeate. Any components larger than the pore size simply cannot pass through, and remain behind in what is called the retentate.

The surface of the membrane is kept free of blockages by the force of the liquid flow moving parallel to the membrane surface.

Alfa Laval membranes

Membrane filtration is becoming increasingly popular in high-hygiene processes that include:

- concentration and purification

- clarification and fractionation

- extraction

- product recycling and recovery

- product and effluent upgrading

The range of flat sheet membranes from Alfa Laval covers all cross-flow filtration processes: reverse osmosis, nanofiltration, ultrafiltration and microfiltration. The membranes are available by the metre, as 20 x 20 cm sheets or cut into flat sections to fit into all configurations of the unique plate-and-frame modules, also manufactured by Alfa Laval.

Benefits of Alfa Laval flat sheet membranes

- wide range of different membrane types

- all filtration processes covered: reverse osmosis, nanofiltration, ultrafiltration and microfiltration

- resistant to high temperatures and pH

- all materials comply with EU Commission Directive and FDA regulations

- available by the metre, as standard sheets or pre-cut to fit into Alfa Laval plate-and-frame modules

- own Alfa Laval manufacture

How it works

Microfiltration

Microfiltration (MF) membranes from Alfa Laval are extremely cost-effective to operate, largely as the result of the low energy consumption involved. They also have the advantage of eliminating the frequent replacement and disposal of the cartridges and other consumables used in traditional dead-end filtration

Alfa Laval microfiltration membranes are extremely durable, with service lives that can extend over more than five years

Microfiltration is used on feed streams where the aim is to remove small-diameter dispersed solids such as bacteria, fat and oil globules without affecting the balance of the components dissolved within the stream.

Ultrafiltration

Ultrafiltration (UF) uses membranes in which the pores are somewhat smaller, with a cut-off range from 1,000 to 100,000 Molecular Weight (MWCO), and where the applied pressure is relatively low.

Salts, sugars, organic acids and smaller peptides pass through the pores of the membrane, whereas proteins, fats and polysaccharides do not.

Using appropriate ultrafiltration membranes also makes it possible to fractionate a feed stream into two distinct streams. Each contains dissolved components with different molecular weights.

Nanofiltration

Nanofiltration (NF) uses membranes with pores that are even smaller - down to 300 daltons. Operating at pressures of up to 50 bar, small ions pass through, whereas larger ions and most organic components do not.

Alfa Laval nanofiltration membranes are used for the high-yield concentration and demineralization of products such as whey and ultrafiltration permeate. These special membranes are used for filtering out large salts with a divalence in excess of 2, while small monovalent salts pass into the permeate. They can also be used in producing low-alcohol beverages, because the alcohol component passes through the membrane, while the colour and aroma remain in the retentate.

Reverse osmosis

Reverse osmosis (RO) uses membranes with pores to minute that only small fractions of salts can pass through, along with the water that is the prime component of the permeate.

Certain organic compounds with low molecular weights can also pass through - but only to a limited extent. However, it is impossible for any other components suspended or dissolved within the liquid flow (salts, sugars etc.) to do so.

Alfa Laval reverse osmosis membranes are used for the high-flux concentration of either the direct feed stream or permeates from ultrafiltration and nanofiltration.

Compliances

All materials used for the production of Alfa Laval membranes, in both spiral-wound and flat-sheet membrane designs and configurations, comply with EU Regulation (EC) 1935/2004, EU Regulation 10/2011, EU Regulation (EC) 2023/2006 and FDA regulations (CFR) Title 21. The membranes are thus suitable for use within food and pharmaceutical processing applications.

These compliance also extend to the equipment and fittings related to membrane operations, including items such as plate-and-frame units, element housings and pumps.

Cleanability

Most types of membranes are cast onto a backing material made of polypropylene, making them capable of withstanding high temperatures and high pH values.

These so-called pHt membrane types can operate continuously at high temperatures and also withstand high-temperature (75°C) cleaning with pH values in the range 1-13.