BlueVap

The BlueVap thermal separation system turns black water effluent from olive oil extraction into clear water that can be safely discharged to local sewage plants.

Clear water and concentrate

The municipal wastewater plants in many countries normally refuse to accept black water effluent from olive oil extraction.

That’s why Alfa Laval has developed the BlueVap closed-loop thermal separation system specifically to deal with the challenging properties of such effluent flows. This eases the disposal burden on olive oil producers, as well as rolling back disposal costs.

The BlueVap system turns black water effluent into clear water that can safely be either used to irrigate fields or discharged to any appropriate local sewage plant, and a biodegradable concentrate that can be mixed with husk.

Pre-assembled and fully automatic

The BlueVap thermal separation system is a pre-assembled, fully automatic treatment set-up designed for the continuous processing of black water from olive oil production.

BlueVap features the most resilient evaporator technology currently available, based on Alfa Laval’s world-leading heat exchanger know-how. The system provides exceptional thermal efficiency combined with very low electricity consumption per kg of treated black water, resulting in remarkably low operating costs.

Black water (100%) before treatment with BlueVap

Clear water (80%) after treatment

Concentrate (20%) after treatment

Benefits

- Proven, reliable solution

- Low effluent treatment costs

- Compact, “plug and play” unit that’s easy to install with a minimum of disruption

- No steam or cooling water required

- High resistance to fouling

- Automated, user-friendly operation – only minimal supervision required

Darbības pamatprincipi

How it works

Advanced evaporation technology for treating black water from olive oil production

The BlueVap treatment system is designed to take into consideration that many olive oil producers do not have supplies steam or cooling water readily available.

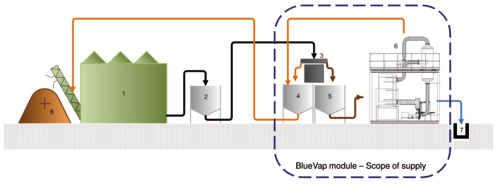

After the black water has undergone initial filtration, the BlueVap thermal separation system therefore uses advanced Alfa Laval evaporation technology to separate this wastewater flow into two fractions – clear water and concentrate.

Approximately 80% of the treated black water ends up as clear water that can be used to irrigate fields or safely be discharged to an appropriate local sewage system. The remaining 20% consists of a biodegradable concentrate that is normally added to the husk from the decanter centrifuge in the olive oil mill, or burned for cogeneration.

BlueVap technology is available with processing capacities up to 1,000 litres/hour or 2,500 litres/hour.