Brew sērijas

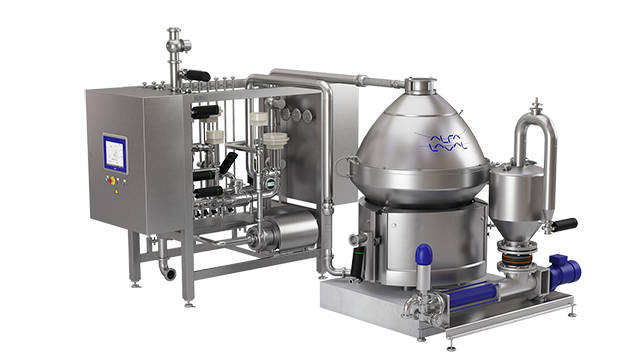

Alfa Laval disku steku centrifūgas jau sen ļauj alus darītavām visā pasaulē sasniegt augstākus apjomus, apmierināt pieprasījuma izmaiņas un saglabāt rentabilitāti. Tos izmanto iepriekš dzidrināšanā, zaļajā alus atdalīšanā, karsto zāļu atdalīšanā un alus atgūšanā, tie nodrošina minimālu skābekļa savākšanu, braucot caur separatoru, un visaugstākos higiēnas standartus.

Augsta alus atdalīšanas efektivitāte apvienojumā ar energoefektīvu darbību

- Centrifugēšana nodrošina alus darītavām ātru alus dzidrināšanu bez aromāta vai CO2 zuduma

- Palielinātas precizēšanas iespējas: samazināta filtrēšana ar preclarification

- Augstas efektivitātes alus atdalīšana nodrošina ātrāku fermentācijas tvertņu apgrozījumu

- Samazināti produkta zudumi: alus centrifugēšana rada vairāk koncentrētu cietu vielu, salīdzinot ar gravitāciju

- Patentēta alus brūvēšanas iekārta un hermētiskais dizains noved pie zemas līdz nulles skābekļa savākšanas

Dzidrināšana ar atdalīšanu palīdz paaugstināt gala alus stabilitāti. Mūsu alus brūvēšanas iekārtas nodrošina saudzīgu produktu apstrādi, izmantojot unikālu hermētiskās barības dizainu. Duļķainuma mērīšanas sistēma un bļodas ātruma regulēšanas funkcionalitāte ļauj sasniegt cietvielu brīvo kristālu dzidro alu, kā arī dūmainos alu

Alfa Laval ir viens no lielākajiem augstas kvalitātes nodalīšanas iekārtu krājumiem pasaulē alus ražošanas nozarei. Mūsu centrifūgas ir izrādījušās ļoti svarīgas, lai alus darītavas visā pasaulē varētu sasniegt lielāku peļņu un lielāku efektivitāti, kā arī lai palīdzētu tām apmierināt mainīgos patērētāju pieprasījuma modeļus, vienlaikus saglabājot rentabilitāti. Alus darītavas centrifūgas no Alfa Laval nodrošina minimālu skābekļa ņemšanas līmeni, braucot caur separatoru, kas ir būtiska kvalitātes prasība alus darītājiem. Higiēna ir arī galvenā uzmanība visos mūsu alus darītavu centrifūgu izstrādes aspektos.

Brew sērijas alus centrifūgas izmanto šādās alus ražošanas procesa lietošanas stadijās:

· iepriekšējs precizējums

· zaļā alus atdalīšana

· karstās zāles atdalīšana

· alus atgūšana

Ar tādām īpašībām un iespējām kā, piemēram, mūsu pilnībā hermētiskais ronis, kas nodrošina minimālu skābekļa izdalīšanos dzidrajā šķidrumā, SmartEject pašiedarbināšanas sistēmu, kas nodrošina neregulāru izdalīšanos ar cietām vielām, kam ir augsts sausnas saturs, īpaši konstruēta mainīgas frekvences diskdziņa (VFD) sistēma nodrošina priekšrocības, kas ietver zemu iedarbināšanas strāvu un īsu enerģijas padevi, un daudz vairāk, ja selektors var pielāgot separatora veiktspēju un jaudu attiecīgajam lietošanas uzdevumam.

Brew range

Brew 20

Multi-purpose centrifuge for craft brewers and microbreweries

- Up to 15 hl/h

- Low oxygen pick-up, <10 ppb– axial hermetic outlet

- ProCarb - Inline carbonation option available

- Low maintenance costs

Brew 80

Multi-purpose centrifuge for craft brewers

- Up to 50 hl/h

- Low oxygen pick-up – axial hermetic outlet

- Turbidity triggering of solids discharge (included in upgraded Plus version)

- Capacity control by inlet turbidity (included in upgraded Plus version)

Brew 80

Multi-purpose centrifuge for craft brewers

- Up to 60 hl/h

- Low oxygen pick-up, <10 ppb – hermetic outlet

- ProCarb - Inline carbonation option available

Brew 301

Multi-purpose centrifuge for small breweries

- Up to 200 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 250

Polisher and multi-purpose centrifuge for small breweries and сraft brewers

- Resource efficient clarification up to 180 hl/h

- ProCarb - Inline carbonation option available

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 250 Plus

Polisher for small breweries and craft brewers

- Up to 180 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Basic and easy to operate

- Skid-mounted separator and system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 350

Polisher and multi-purpose centrifuge for medium size breweries and craft brewers

- Up to 300 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 350 Skid

Polisher for medium size breweries and craft brewers

- Up to 300 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

-

Up to 60% energy savings when compared to traditional design

Brew 501 H

Multi purpose for larger size breweries and craft brewers

- Up to 500 hl/h

- Center to Center

- Zero oxygen pick-up and low power consumption

- Complete system with full flexibility

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 600

Multi-purpose for larger size breweries and craft brewers

- Up to 650 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 600e

Multi-purpose for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 701

Polisher for larger size breweries and craft brewers

- Up to 650 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 701e

Polisher for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Very low power consumption with eDrive (direct drive)

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley automation

Brew 701 eMotion™

Polisher for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Extremely low power consumption with eDrive (direct drive) and eMotion (reduced air friction)

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley automation

How it works

The heavier solids phase is collected at the periphery of the bowl, where it is discharged intermittently via the centrifuge cyclone. The solids are discharged by a hydraulic system below the separation space in the bowl, which forces the sliding bowl bottom to drop down at suitable intervals, thus opening the solids ports at the periphery of the bowl.

Craft brewing

Share your passion for craft brewing

Commercial brewing

The best equipment for the best beer