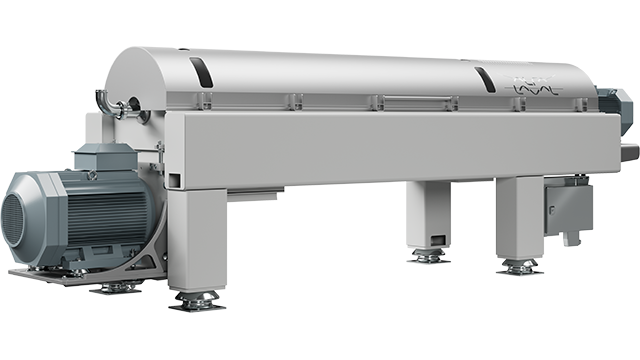

ALDEC G3

The ground-breaking ALDEC G3 decanter is the result of a rethink of the basic parameters of decanter centrifuge design and performance.

A new set of parameters

Alfa Laval unparalleled decanter centrifuge technology has paved the way for a series of ground-breaking innovations, all based on proven technology renowned for reliability. Together, these ensure a unique combination of better performance and lower energy consumption, resulting in lower operating costs than ever before.

The ALDEC G3 decanter is built around the Slimline design – a breakthrough in decanter centrifuge performance and capabilities. The smaller conveyor diameter makes room for more liquid in the pond, and allows higher bowl wall pressures, resulting in either drier cake or using less polymer.

Patented Alfa Laval Power Plates also effectively reduce the power consumption of ALDEC G3 decanter centrifuges, making a big contribution to cost savings.

Multiple benefits

The ALDEC G3 range ensures:

- Lower power consumption (which also greatly reduces CO2 emissions)

- 10% boost in processing capacity – or drier cake

- Reductions in life cycle costs

- More efficient bio-solids handling

- Better process monitoring and control

The ALDEC G3 decanter centrifuge design provides significantly improved separation results and better control of all the variables – using up to 40% less energy. Lower power consumption saves money as well as improving the environmental profile of any dewatering or thickening operation.

Events

Darbības pamatprincipi

Working principle

In the ALDEC G3 decanter centrifuge design, the feed enters the horizontal cylindrical bowl through a stationary inlet tube and is accelerated smoothly by an inlet rotor. The resulting centrifugal forces make the solids collect on the wall of the bowl. The screw conveyor and the bowl rotate in the same direction, but at different speeds. This moves the solids towards the conical end of the bowl, where they can be removed. The now-clarified liquid components in the sludge flow leave the bowl by flowing over adjustable plate dams into the casing.

The distinctive ALDEC G3 design enables the hydraulic pressure inside the bowl to enhance scrolling through a constriction between the baffle disk and the bowl wall. This boosts efficiency, because only the very driest fraction of the sludge cake passes from the bowl into the casing through the 360° solids discharge openings.

New performance parameters

The special Slimline design significantly increases the volume available inside the bowl. This unique set-up boosts processing capacity at the same time as ensuring the most efficient performance.

The combination of the deep pond and the smaller discharge radius saves as much as 20% on your power costs, because less energy is lost when the bowl rotates.

Power plates

The kinetic energy in the liquid that leaves the decanter is proportionate to the square of the velocity. The patented Power Plates in the ALDEC G3 design make it possible to capture some of this kinetic energy from the liquid discharge, transferring it in the opposite direction of the bowl rotation. This reduces the total effluent velocity, which means less energy is needed to achieve any given effluent flow specifications.

The benefits for you

Your power consumption will decrease, which in turn will save you money and bring you closer to meeting environmental regulations.

2Touch control package

ALDEC G3 decanter centrifuges are equipped with a 2Touch control package as standard. This makes it easy to fine-tune and improve productivity throughout the service life of each ALDEC G3 unit.